wire edm machine full form

Deionized water as an active medium ensures a sufficiently. Wire edm machine full form Sunday June 12 2022 Edit.

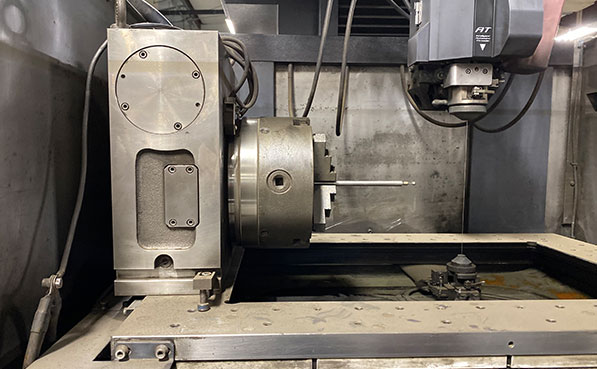

Over 20 Ram Edms Accurate Cavities About Rotary Edm

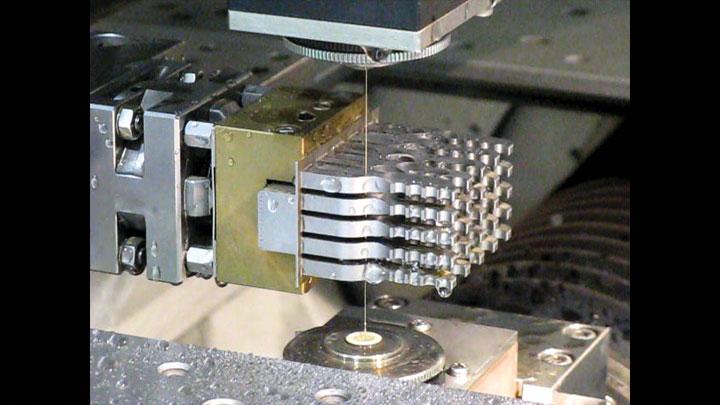

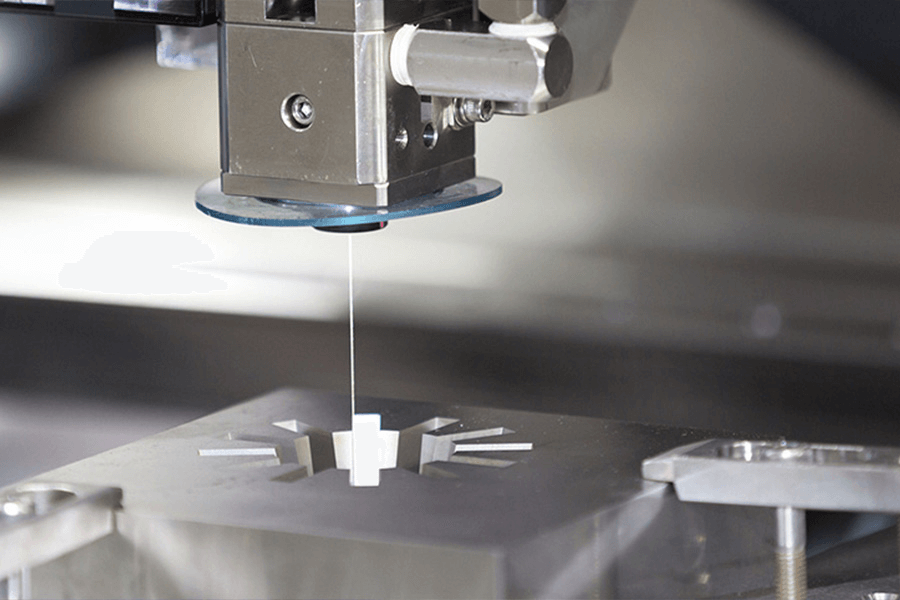

Wire EDM also known as Wire-Cut EDM works in a very similar way using a rapidly charged conductive metal wire to melt the material.

. MV1200-S ADVANCE TYPE M800. Wire Electrical discharge machining Wire EDM is a manufacturing process that uses electrical sparks to form metal shapes. Four Axis Independent UV Work.

Wire EDM machines manufactured to maximize reliability. You all know about conventional. They eliminate all the classic errors such as backlash expansion and wear effects.

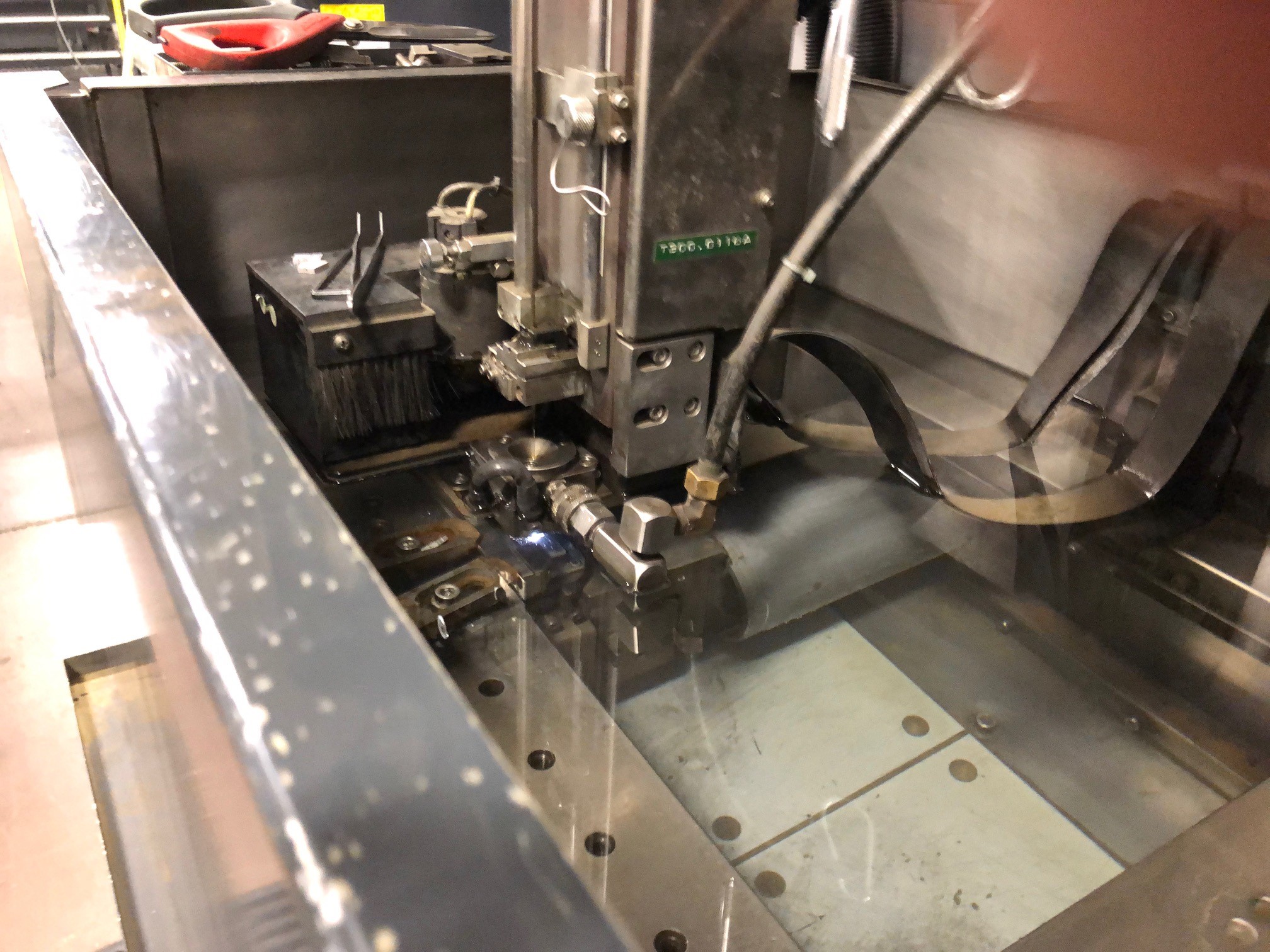

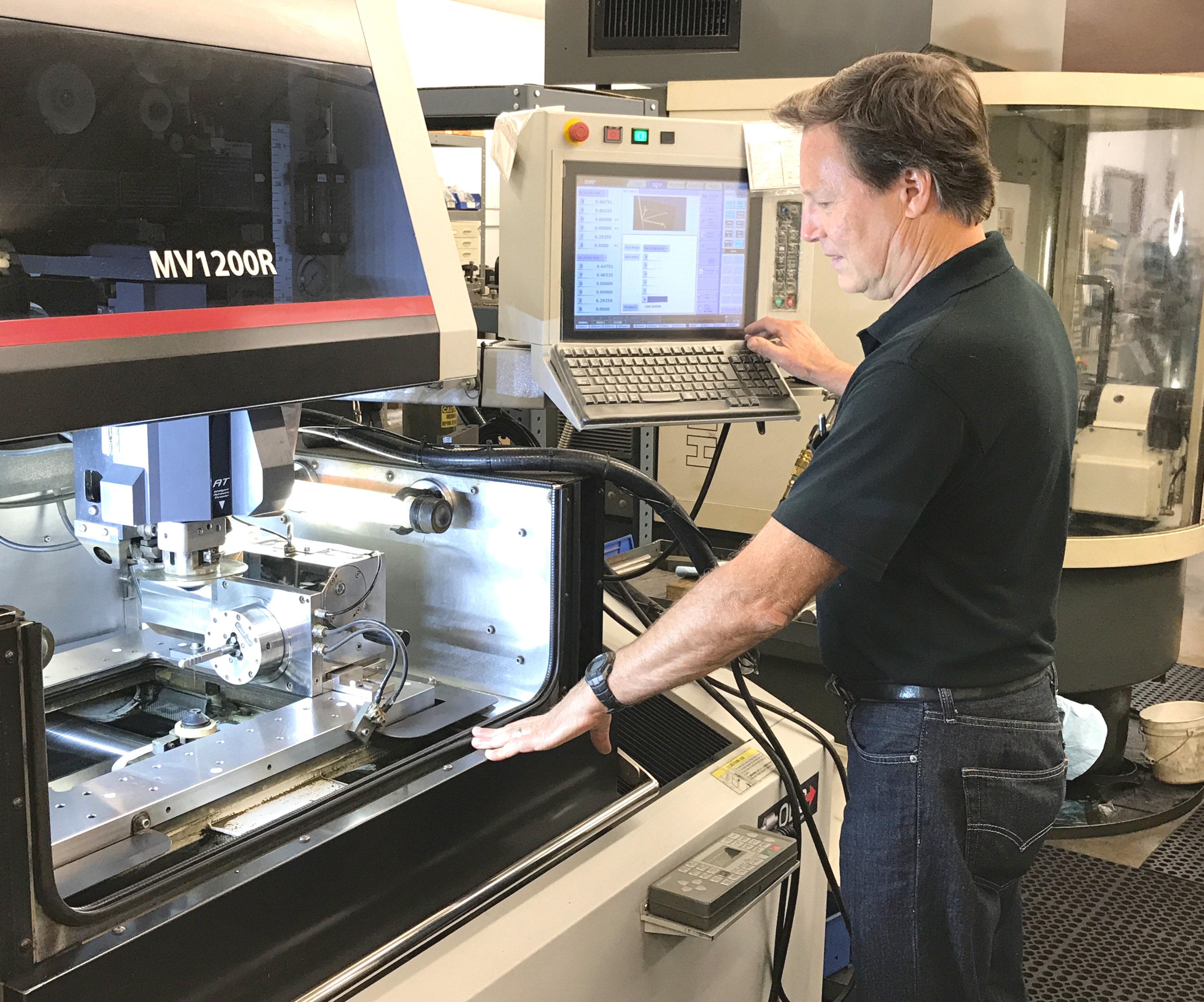

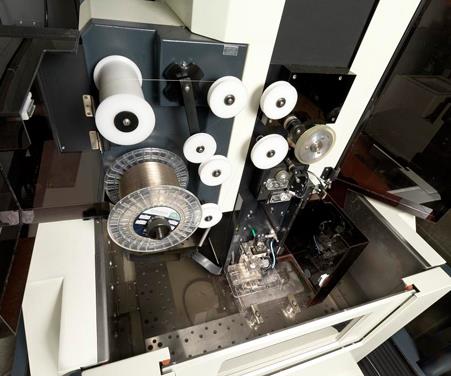

The industrys 1 Wire EDM. Reduce small parts manufacturing costs with the highly-precise MV1200-S Advance M800 Mitsubishi Wire EDM. In wire electrical discharge machining WEDM also known as wire-cut EDM and wire cutting a thin single-strand metal wire usually brass is fed through the workpiece submerged in a tank.

Though the first wire-cut electrical discharge machines came online in the 1960s the history of EDM actually dates back to the 18th century. Sodick Wire Edm Machine With Rotary Indexing Table Option Kitchen Appliances Espresso Machine Edm Wire. Though the first wire-cut electrical discharge machines came online in the 1960s the history of EDM actually dates back.

The material is thermally removed by the electrical discharge between the continuous wire electrode and the metallic base. Wire Electrical discharge machining Wire EDM is a manufacturing process that uses electrical sparks to form metal shapes. Wire edm machine full form Sunday June 12 2022 Edit.

The axis servo control system developed by GF Machining Solutions for die-sinking EDM machines is a closed. All the knowledge of our experts to offer you a compact economical and quality machine. Work Piece Up To 26 inch Long X.

30 plus yrs experience in creating custom wire forming to customer specification. Work Piece Up To 26 inch Long X 14. Because of these sparks EDM is also known as spark.

No actual contact is made between the. 400 a 600 mm 157 a 3937 in. A wire EDM machine can.

A major advantage of wire EDM over conventional EDM is that the continuous supply of wire minimizes the wear that occurs with a fixed electrode.

Sodick Wire Edm G Codes M Codes Helman Cnc

Wire Edm Services Edm Machining Wire Edm Peko Precision

Wire Edm Machining For Extreme Accuracy Explained Mellowpine

Wire Edm Services Michigan Edm Machining Metalmite

Sinker Edm Vs Wire Edm Main Differences And Applications 3erp

Flexibility Quality And Savings With Wire Edm Solution

Edm Performance Up Manufacturing Costs Down

Cam Simulation Gets Toolmaker Up To Speed With B Axis Edm Modern Machine Shop

Edm 101 Electrical Discharge Machining Basics Engineering Com

Milco Wire Edm About Our Company

The Hidden Cost Of Edm Wire Consumption Modern Machine Shop

Used Sodick Wire Edm Aq535l Cnc For Sale Liberty Machinery

Importance Of Wire Edm Machine Maintenance Makino

Wire Edm Machining Cutting Services Moon Tool